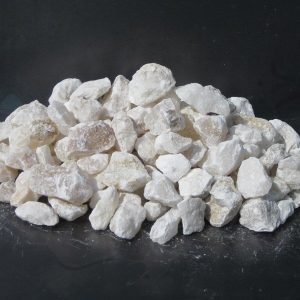

Semnan micronized plaster

Micronized plaster Semnan is a type of gypsum with unique characteristics and properties. It is produced using a mineral substance derived from raw gypsum rock (calcium sulfate dehydrate) and has a very high purity. In the manufacturing process, the mineral substance or Semnan gypsum is crushed and graded, and after calcination, it is milled into a fine powder. Through the use of a separator, micronized grading (in micron dimensions) is achieved. This type of Semnan gypsum has a high mesh size, purity, and smaller particle size in micron dimensions.

Characteristics of Micronized plaster Powder Semnan:

One of the main and important characteristics of this gypsum powder is its mesh size and particle size. Mesh size 200 and particle size below 175 microns are common numbers associated with this product. The significance of this characteristic lies in its impact on the mechanical, structural, and physical appearance properties of the product. This particle grading and softness can have various applications in the construction industry and other industries.

White and shiny color: The white and shiny color of Micronized plaster makes it an ideal base for whitewashing and interior decorations.

High purity: This type of Semnan gypsum has a high level of purity and, as a natural mineral substance, is usually free from harmful impurities. A purity level of over 98% is expected in this type of gypsum.

Setting time: Another characteristic of this gypsum powder is its higher initial setting time compared to regular gypsums. This feature provides the manufacturer with more time for final finishing, as it has a longer initial setting time and allows for proper final setting.

Strength: The flexural strength of this gypsum powder is usually higher than 2.5 N/mm². This feature is highly significant as gypsum may not be considered a material subject to bending in construction, but high flexural strength increases its quality over time.

No need for sieving: Micronized plaster powder does not require sieving and is naturally soft and smooth. This feature greatly facilitates working with it.

Another notable feature is its permeability to moisture. This gypsum powder can preserve building structures against moisture and assist in maintaining a comfortable indoor environment in areas with high humidity.

Micronized plaster powder is easy to use and does not require sieving. By mixing water with the gypsum powder, a sticky gypsum mixture can be easily prepared for use in construction and interior decorations. Additionally, this product has good adhesion properties and can be satisfactorily applied on various surfaces such as walls, ceilings, columns, and between other building materials as a bonding agent.

Breathability: Micronized plaster Semnan breathes well and absorbs and releases moisture, facilitating moisture control within the building and contributing to the building’s moisture and structural health.

Thermal and acoustic insulation properties: Due to its gypsum structure, this material has thermal and acoustic insulation properties and can contribute to improving the building’s insulation.

Overall, Micronized plaster Semnan has features such as proper mesh grading, higher initial setting time, high flexural strength, softness, low permeability to moisture, high productivity, and ease of use. These characteristics make Micronized plaster powder suitable for use in the construction industry, ceramics and pottery industry, mold making, and other related industries.

High productivity is also one of the gypsum’s features. This product has higher productivity compared to other gypsums, requiring a smaller amount to cover a specific surface. This leads to time and cost savings in construction.

Micronized plaster Semnan Price

With over 40 years of experience in producing microcrystalline gypsum, we guarantee the highest quality for you. The quality of this product depends on factors such as the raw material mine, extraction and production machinery, production knowledge, production conditions, experience, and storage and packaging methods.

We have proven our credibility by consistently being present in domestic and international markets. To obtain the price of Micronized plaster Semnan, you can contact us at +98 23-33445393 and +98 9121319065. It is important to note that Semnan gypsum is not only unique in Iran but also on a global scale, and you can request the highest quality at the best price from IRGYPSUM.

Applications of Micronized Gypsum:

Micronized gypsum is a type of gypsum powder that has exceptional mechanical properties and a high mesh grade. These characteristics have led to the use of micronized gypsum in various fields. Here are some diverse applications of micronized gypsum:

- Plastering walls, columns, ceilings, and other architectural elements.

- Decorative and ornamental plasterwork.

Mold making and casting in various industries.

Mold making and casting in various industries.- Creating decorative false walls and facade molds.

- Production of polymer and composite gypsum products.

- Medical industry: Micronized gypsum is used as a base powder in various medical applications.

- Manufacturing sanitary ceramics.

- Sculpture making.

- Cement work.

- Ceramic production.

- …

Exporting Micronized plaster from Semnan:

Micronized plaster from Semnan is a favored product for export by traders. Semnan gypsum is well-known for its exceptional quality in Iran and other regions of the world. With its high mesh size and popularity, micronized gypsum from Semnan is a suitable option for export. For packaging this product, regular polypropylene (PP) bags are used, but for better export, it is recommended to use laminated two-layer bags or AD star waterproof bags to avoid any issues during the export process.

Methods of exporting plaster:

Micronized plaster from Semnan is exported to countries such as India, China, and countries around the Persian Gulf using two-layer bag packaging from Bandar Abbas (Shahid Rajaei Port). Additionally, exports of micronized plaster are also carried out to countries such as Iraq (Kurdistan and southern Iraq), Afghanistan, Russia, Armenia, Turkmenistan, Georgia, Kuwait, Qatar, Jordan, Indonesia, Turkey, Middle East, and Africa.

Method of Producing Micronized plaster:

The method of producing micronized plaster is one of the most advanced techniques in the gypsum industry, offering various applications in different industries. With the design of new grinding mills and modern separators by engineers in this industry, the production of micronized plaster has been improved in factories. Micronized gypsum can be produced in different mesh sizes, indicating its ability to pass through very fine sieves.

The process of producing this type of gypsum is similar to the production of specialized gypsum for plastering, with the addition of a device called a separator. In this stage, the gypsum undergoes classification and is transformed into micronized plaster with specific mesh sizes.

More precisely, the production method of this type of gypsum is very similar to specialized gypsum for whitewashing, with the difference that in the micronized gypsum production line, a device called a separator is present. The separator’s function is such that, based on its calibration, gypsum particles up to a specific size can pass through its blades, while other particles are either transferred to the silo as grit or returned to the mill for further grinding and pulverization.

Separators can be divided into two types: dynamic and static, each with its own specific functions. Using various types of separators, micronized powders with particle sizes ranging from 11 to 0.002 millimeters or mesh sizes of 18 to 3500 can be produced.

During the production of micronized gypsum, it is important to ensure that all production processes, storage, and handling are in compliance with the national building regulations of Iran and the Iranian national standards.

Micronized plaster in Construction:

This article discusses the applications of micronized gypsum in the construction industry. Considering the abundance of gypsum deposits in Iran, the price of micronized plaster is relatively lower compared to other similar construction materials, making the production, use, and purchase of micronized gypsum economically viable in the Iranian market. The type of gypsum used should be selected based on its intended use. Fine grained gypsum is used for plastering and finishing, while coarse grained plaster is suitable for base layers.

High-quality micronized plaster, produced with suitable raw materials, is recognized as a versatile gypsum used in construction. This article emphasizes the importance of selecting the appropriate plaster based on its intended use, strength, and adherence to production standards in buildings. Micronized gypsum is well-known in Iran as a widely-used product in the construction industry due to its affordable price and high quality. Proper storage conditions are also of special importance to ensure that the plaster remains usable.

Method of Storing and Warehousing Micronized plaster Powder:

To preserve the quality and properties of micronized plaster powder, it is essential to follow proper storage and warehousing methods. The effective methods for storing this product under standard conditions are described below:

- Use of pallets: It is recommended to place the micronized gypsum on plastic or wooden pallets. It is advisable to stack a maximum of 10 bags of gypsum on top of each other on a single pallet and then place the pallets in a suitable environment.

- Distance from walls: If the pallets are stored in a closed environment without proper ventilation, it is important to maintain a minimum distance of one meter between the micronized gypsum bags, walls, and between the pallets themselves. This allows air circulation between the bags and prevents moisture buildup and the formation o

f voids.

f voids.

- Storage in humid areas: If long-term storage of micronized gypsum is required, it is better to store it in

a dry and sealed location. In humid areas, measures should be taken to reduce the storage duration. Optimal and timely use of micronized gypsum in such conditions helps prevent infiltration and changes in its properties.

In general, micronized plaster powder can be used for more than one year if it does not come into direct contact with water. By following these storage and warehousing methods, the quality and effectiveness of this product can be preserved over time.